Description

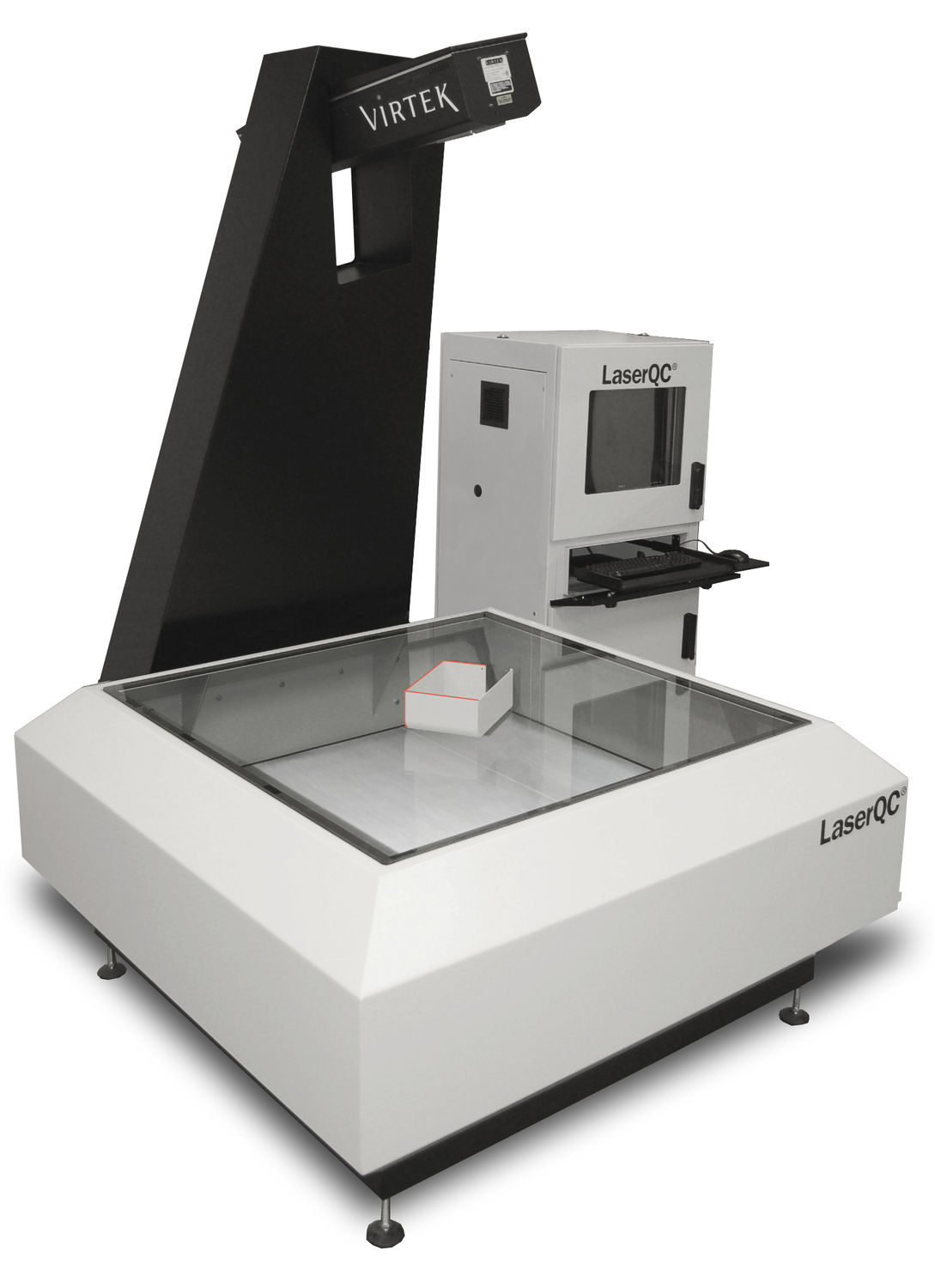

LASERQC® is the premier self-calibrating laser inspection system in its class. LASERQC® dramatically increases throughput in precision sheet metal, precision foam, leather, aerospace and gasket fabrication. The system is designed for first article inspection, quality reporting (SPC, ISO, LEAN, etc), reverse engineering and automatic formed measurement.

A rapid inspection system for the sheet metal and gasket fabrication industry

The LASERQC® delivers the kind of bottom-line benefits that help your shop build and retain business - faster turnaround, increased throughput, lower costs per part, reduced scrap and rework and ultimately higher customer satisfaction

Laser Fast

LaserQC® captures over 500 data points per second to make part inspections laser-fast, right on the shop floor.

Laser Accurate

The system quickly performs 100% inspections accurate to ± 0.002” (0.05mm) for 2D measurements and ± .010” for Formed (3D) measurements

Shop Floor Friendly

LaserQC® offers a reliable, lowmaintenance solution that operates along side your facilities CNC equipment. LaserQC® self-calibrates and adjusts system settings to accommodate for environmental changes common to the shop floor.

Fast and Easy

LaserQC® is designed to set up easily so your system is up and running in less than a day. The intuitive user interface allows new operators to become fully proficient within just a few hours.

Customer-Proven Performance

Insight from industry leaders in precision sheet metal work makes the LaserQC® a proven performer on the shop floor. In use by more than 1500 companies worldwide, the LaserQC® is utilized in applications ranging from aerospace and high-tech to cabinetry and heavy equipment manufacturing.

| Scanning Accuracy* | LaserQC® 800 and 1200 |

| ±0.05mm (0.002”) (2D only) | |

| ±0.25mm (0.010”) for height measurement | |

| LaserQC® Expert | |

| ±0.13mm (0.005”) (2D only) | |

| Maximum Part Thickness | 200mm (8.0”) for 2D, 305mm (12.0”) for AFM |

| Calibration | Automated |

| Maximum Scan Zone | LaserQC® 800 - 760mm x 760mm (30” x 30”) |

| (single scan): | LaserQC® 1200 - 1220mm x 1220mm (48” x 48”) |

| LaserQC® Expert - 2440mm x 1220mm (96” x 48”) | |

| Oversized Parts | Capable with merged scan feature |

| Overall Dimensions (LxWxH) | LaserQC® 800 - 1575mm x 1220mm x 2440mm |

| (62” x 48” x 96”) | |

| LaserQC® 1200 - 2007mm x 1651mm x 2440mm | |

| (79” x 65” x 96”) | |

| LaserQC® Expert - 2870mm x 2057mm x 2612mm | |

| (113” x 81” x 103”) | |

| Operating Environment | 10 - 38°C (50 - 100°F) |

| Power Requirements | 11OV/60 Hz or 240V/50 Hz |

| Laser Device & Output | Laser diode device with maximum 4.5mW output |

| Laser Class | Class IIIa, meeting the 21CFR 1040 standard |

| for CDRH certification in North America | |

| Class 2M, meeting the | |

| 60825-1:1993+A1:1997+A2:2001, standard for | |

| CE certification in Europe | |

| Software | Includes inspection, SPC and reverse engineering |

| Computer System | Current model PC with monitor, color printer, |

| keyboard and mouse | |

| Operating System | Windows® 7 |

| Warranty | One-year warranty on hardware and software |

| Extended Warranty | Optional |

| Extended Support Program | Optional |

| Part Stabilizer | Optional |